Interchange Filter Manufacturer | DML

High-quality | Reasonable-price

KNOW DML

Provides over 48500 standard model number of Interchange filter, use for industrial equipment, and heavy mobile equipment.

The same filtration efficiency of the original filter element but It’s cost-effective.

Flexible automated product lines and customized printing to services The Equipment User, Traders, and Brand Owner.

Nearly 10 years of ODM experience to service German filter element brands, we have the confidence to help you get the stable quality, and timely delivery, and no MOQ

As your wish

the interchange filter you get will pass the actual filtration rating Inspection, and the filter media has to go through precise calculation before it is produced and formed ( beta ratios, differential pressure, flow capacity, etc.)

Interchange Filter Suitable For You

DML provides hydraulic oil interchange filter, use for the hydraulic system in industrial equipment, and heavy mobile equipment.

Mainly shows you the hydraulic line filter element. Such as:

- Suction Strainer

- High-pressure Filter

- Hydraulic Return Filter

| Filter Media | Stainless Steel Mesh | Glass Fiber | Cellulose |

| Micron Rating | 3~400μm | 1~70μm | 5~40μm |

| Operating Temperature Range | -20℃ ~ 160℃ | -20℃ ~ 160℃ | -20℃ ~ 160℃ |

| Max Operating Pressure | 420bar | 420bar | 420bar |

- The stainless steel mesh structure

- Can be washed repeatedly

- Excellent filter efficiency

- High flow capacity

- Great filtration ratings

- High-pressure filter

- Medium-pressure filter

- Low-pressure filter

- Reasonable price

- High-temperature resistance

- High-pressure resistance

- Great filtering ratings

- Excellent filter efficiency

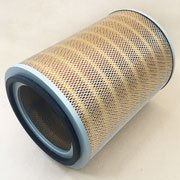

Air Compressor Filter

air filter | oil filter | oil separator

And compressed air filter, servo valve filter, and other filter elements, cover all kinds of pneumatic machinery, petrochemical industry, gas pipeline transportation, automation equipment, etc.

Not include filters for subsequent equipment, such as refrigeration compressors, compressed air drying equipment, liquid separation equipment, etc.

Air Filter

- Dust collector filter, filter bags, and panel filter

- High-quality filter media

- High dust holding, good efficiency

Oil Filter

- External oil filter

- Inline oil filter element

- Excellent filter efficiency

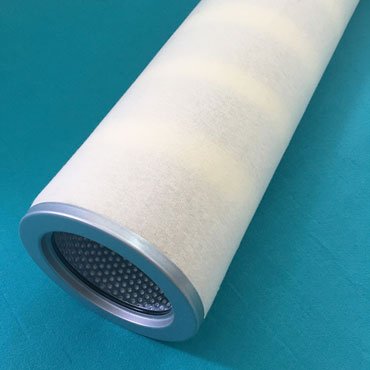

Oil Separator

- Imported glass fiber filter media

- SS304 skeleton choosable

- The oil content of compressed air is less than 0.03ppm

Industrial Air Filter

Mainly provide Industrial dust filter element, Including dust filter cartridge, panel filter, and filter bags.

Suitable for heavy mobile equipment, laboratories, sterile rooms, machinery manufacturing, agriculture and forestry, air compressor equipment, etc.

Particle Removal Efficiency: 99.90% (β1 = 1000) @ 1 micron.

Multity types of structure, Filter ratings choosable.

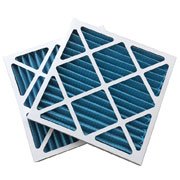

Panel Filter

Large size for industrial filtration equipment

High-temperature resistance

Deep filtration effect

Filter Bags

Industrial filter bags

Industrial filter bags

Excellent filtering efficiency

High dust holding capacity

Industrial Water Filter

Large Flow Water Filter

High flow rate, low pressure loss

Non-metal structure, easy to Installing

Longer serve life

String Wound Filter Cartridge

Apply to acids/ bases, etc fluid environment, non-organic solvents such as chemical solutions

Excellent filtering performance

Melt Blown Filter Cartridge

No chemical binder

Differential pressure less than 0.2bar

Longer serve life

PP Pleated Filter

No chemical binder

No leakage

No secondary pollution

Coalescing Filter

Coalescing filter element use high-density gradient glass fiber, Efficient coalescence of liquid mist and droplets in the airflow, high filtration accuracy

Stable structure, no media fiber shedding, won’t cause pollution to the environment and downstream products. Great compatibility with various fluids.

Environmental protection, completely burned without residue.

Suitable for:

aviation fuel, petrochemical industry, turbine oil,

and other low viscosity hydraulic oil, lubricating oil, etc.

Glass Fiber Sintering Filter

Borosilicate Glass Microfibres bonded

Generally used to remove oil, particulate impurities, and aerosols in gas

Beta 10000/99.99% retention ratings from 0.1μm

Filter Element Used For Servo Valve

- High filtering ratings, Good filtration efficiency

- Maintain the oil cleanliness of the servo oil system

- Very friendly to precision instruments

Suitable for industrial fluid systems

Such as aviation, aerospace, automobiles, ships, metallurgy, energy, petrochemical, medical equipment, heavy machinery, etc.

Filter Disks, Filter Mesh

Mainly used for oil filtration in filter presses machine, oil system filtration of ships, diesel engines, and other equipment, as well as the filtration of impurities in textile raw liquid

- Filtering accuracy: 5~202μm

- Specification: 40/20 65/30 90/30 90/45 125/60 155/70 175/90

- Filter media: Phosphor Copper Mesh, stainless steel mesh, etc…

Compressed Air Filter Element

Depending on the difference of the working environment, pressure of system, and filter media, the precision filter element can be used to filter liquid water, solid particles, gas-liquid separation, etc.

DML mainly provides production and sales of interchange filter elements, covering a wide range of industrial use.

Parts of standard model numbers for your information above

Help you to know the scope of DML interchange filter

Why Choose DML Interchange Filter?

How To Purchase Interchange Filter?

We are specialized in filter filed over 23 years.

Mature production technology, and can give you professional technical guidance of installation and use.

Many manufacturing industries must replace the filter element when using filtration equipment, and sometimes will replace the original filter element with another brand of interchange filter.

Including filter element of known brands, also be cross-referenced.

For example:

Donaldson, Parker, Hydac, etc.

So,

If you need to change the interchange filter of the regular model number, that’s easy.

but custom or you want to reduce the filter cost of replacing,

absolutely that you should find a reliable and stable interchange filter manufacturer.

And, be sure to keep a good record of system parameters.

Filter Customized

The information of Working environment, filter media, system pressure, etc be needed

You will get our engineer help to solve all filtration questions