Oil Separator Filter Manufacturer

Oil Separator Filter Meet the Replacement

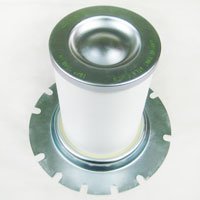

Replacement Oil Separator PN#1622314000

Replace the brand of Atlas Copco Screw Injection Air Compressor Repair Part

- Direct Replace Compatibility 100%

- Good Quality Raw Materials(H&V) Micro Glass Fiber Media Filter

- High-Strength Skeleton

- Cost-Effective

- Working Hours More Than 4000 Hours

- Residual Oil Quantity <3PPM

- Initial Pressure Difference < 0.03MPA

- Certificate: ISO 9000

Replacement Separator Element PN#1604039380

Replace the brand of Atlas Copco

- Filter rating 0.01 Micron

- Oil contained in compressed air is below 3ppM

- Filtration efficiency 99.99%

- Operation life is approximately 3500h-4500h

- Initial pressure differential≤0.02Mpa

- Separator element media made by the glass fiber, which imported from HV & Lydall

- Passed ISO 9001:2000

- No MOQ

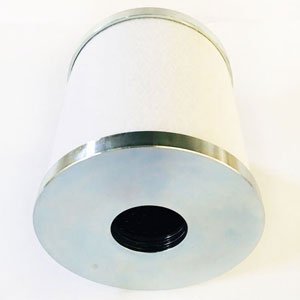

Spin-on Separator Element

Replace the brand of Ingersoll Rand (PN#89259337, PN#24121212, PN#54749247, PN#22354633, etc), and so on.

- OEM /ODM Part reference

- 194 CFM (SPIN-ON), Volume 3.41

- Operating preasure max.20bar

- Operating temperature max.120℃/ 248℉

- Mounting by hand, apply film of oil to gasket

- Fit oil separator box & tighten by clamp

- Do not dismantle oil separator housing while compressor is pressurized

- Change box after flow resistance has reached 1 bar, at latest 1 year of operation

Replacement Separator Element PN#010451050

Replace the brands of Elgi, Compair and so on

- Be used to separate the gas and oil from compressed air.

- Using excellent filter media of glass fiber, the latest technology, and production line.

- These separator elements are stringently tested cause to ensure quality

- Direct Replace Other Brands & Product Compatibility 100%

- Oil contained in compressed air is below 3ppM

- Working life more than 4000h

Oil Separator Filter

Replacement Oil Separator

Interchange Separator Element

Good Separator Filter Element Supply Partner Could be Help You or Your Business

About DML

With a large number of mature design drawings, we provide the replacement separator elements that can completely match the original filter.

You will obtain high-quality oil separator filter while greatly saving replacement costs.

We also provide high-quality brand printing services to customers who operate our own brands, at the same time, more product categories will help you save purchasing time.

ADVANTAGES IN SEPARATOR FILTER PRODUCTION

If you are looking for oil separator filter element products of industrial filter equipment or heavy-duty machinery, such as air compressor filter element, hydraulic filter element, dust removal filter cartridge, etc.,

No matter you are a device user, a trader or a brand operator, DML is always your most trusted choice.

- Now start to match your separator element.

- Please provide the parts number of separator elements you need to replace.

- It will significantly improve our efficiency if there is a reference picture of the old filter element.

- Provide as many detailed requirements as possible to help you get faster and comprehensive feedback.

Mail to info@filterdml.com or send us via the form on the right.

You will get a reply within 6 hours.

Know More About Separator Element

to Help You Choice & Use Correct

What is Oil Separator Filter?

An oil separator filter is a component for separating oil and compressed air. It is generally used in screw air compressors, vacuum pumps, steam turbines, and gas-liquid separation equipment such as crude oil and natural gas.

Service Life

The working life of the oil separator cartridge is slightly different according to the type of oil to be separated and the use environment.

For example,

the air-oil separator of fully synthetic oil has a service life of 6000 hours, while the oil separator cartridge used to separate mineral oil has a mission within 4000 hours, if the use environment is harsh (such as in a dusty environment), its service life will be further shortened.

Because the separator elements cannot be reused by cleaning, they must be replaced in time when the use time exceeds or approaches the set maximum use time, whether it is a spin-on or built-in oil separator filter.

Spin-on Oil Separator Filter

The appearance is the same as the oil filter used in ordinary cars or heavy-duty, but the main function is not to filter but to separate.

Replacement

The replacement method is the same as the oil filter, it can be clamped by a special wrench, unscrewed, and replaced by reverse rotation.

Similarly, when removing the oil separator filter, the separator connector may also become loose, so the separator connector must be tightened first, and be careful of the O-ring.

Built-in Separator Filter Elements

The built-in separator element has a relatively large capacity, which will be fixed and sealed by several connecting screws, and the gasket of the separator element needs to be retained.

The metal nails on the gasket can transfer the static electricity generated by the oil separator to the ground to prevent fire.

If the gasket needs to be replaced due to damage, metal nails must be installed.

Why Use The Oil Separator Filter?

Some special industries or equipment will use oil separator cartridges to achieve a certain purpose during production or operation, and separation procedures must be carried out in this process.

For example:

- Compressing air as a power source. This process needs to ensure the cleanliness of the compressed air to make the energy conversion more direct and efficient.

- For example, in the petroleum industry, the separation and compression of petroleum pyrolysis gas, the oil separator filter can separate the gas of different purposes in the petroleum gas, in order to make other by-products (such as mainly separating crude oil and associated natural gas).

- In short, whether it is gas compression, cooling, transportation, etc., as long as there are certain requirements for the type and properties of air, an oil separator element must be used.

Why Use High-quality Oil Separator Filter?

Because the instability of the air compressor will cause pressure changes, high-quality separator elements need to have a certain pressure resistance.

Influenced by the pressure valve, the oil mist concentration under low pressure will increase, and the flow rate when passing through the oil will increase, which will increase the load of the oil separator cartridge and reduce the separation effect. Finally, increase the fuel consumption. Therefore, the glass fiber thickness of the oil separator cartridge is also very important.

Many screw air compressor problems are caused by the separator element. Poor quality oil separator filter will cause the oil mist to not be separated efficiently.

The oil mist will be discharged with the compressed air, which will corrode equipment components, (such as rubber, plastic, sealing material deterioration, block component gaps, cause valve components to malfunction, etc.), and will also pollute products and reduce quality.

The high-quality separator element can not only ensure the high efficiency of the compressor, but also ensure its long-term service life.

Why Need to Replace The Separator Element?

When the compressor is working, it will entrain large and small oil mist from the compressed air generated in the head part.

Larger oil droplets are easy to condense and separate when passing through the oil and gas separation tank, but the suspended oil mist with a diameter of less than 1μm must pass through the coalescing material in the oil separator to intercept.

How Does It Work?

Through the filtration of the filter material, the oil mist is condensed into large oil droplets and collected at the bottom of the oil separator cartridge, so that the standard compressed air will be discharged by the compressor.

This process will also contain certain solid impurity particles, which are retained in the filter material when passing through the filter layer of the oil separator filter, which will increase the pressure difference of the oil separator element continuously.

The Result of Pressure Up

As the use time of the oil separator cartridge continues to increase, when the pressure difference of the oil separator filter reaches the rated pressure value, the filter element must be replaced.

Otherwise, it will increase the cost of power consumption of the compressor, cause overheating of the machine, or other problems.

It may include:

- Reduce separation efficiency, increase fuel consumption, increase oil content of compressed air, affect air quality and use of back-end equipment.

- If blocked, the piezoresistance will increase, the exhaust pressure will increase, and the energy consumption of the entire unit will increase.

- Insufficient oil return after blockage will cause the exhaust temperature to rise, which will reduce the working life of the oil and the separator element.

- Blockage of the oil circuit and insufficient oil return will reduce the lubrication capacity between the main engine parts, and in severe cases will shorten the life of the equipment.

- If it is damaged due to blockage, a large amount of solid impurities will be mixed into the host, which will cause serious wear of the head.

etc.

When to Replace The Oil Separator Filter?

- Increasing oil content of the air in the air pipe;

- When the pressure valve or the differential pressure indicator alarms, the oil separator filter needs to be replaced;

- High oil pressure;

- Abnormal increase in power consumption;

- The use time has reached the rated use range;

- When the working pressure of the oil separator element is higher or lower than the rated value;

- When the oil and gas separator filter has a burning or charred smell;

- If the working environment is very poor, the oil separator filter should be replaced in advance according to the actual situation.

How to Replace The Oil Separator Filter

It is more convenient to replace the spin-on oil separator filter, which is always the same as the replacement of the oil filter element. Rotate in the opposite direction to disassemble, then clean and replace.

Just pay attention to whether the separator joint and sealing ring are damaged.

The built-in oil separator element is relatively cumbersome to replace.

It is necessary to remove several bolts on the oil separator barrel, as well as some oil pipe joints, air pipe joints, and exhaust pipe joints.

Before replacement, you need to turn off the power, shut down and confirm that the pressure has been released,

Remove the connecting pipe of the pressure valve.

Remove the oil pipe and other control pipes.

Cover plate of oil separation tank.

Remove the oil separator filter.

Replace and seal.

What Is The Difference Between the Spin-on and Built-in Type?

The built-in separator element is mainly installed inside the oil separator tank in a machine with high power and large equipment volume. It has different size structures.

The initial pressure difference is slightly higher than the spin-on oil separator filter.

The spin-on oil separator filter has a small pressure difference and is easy to replace. Generally, air compressor accessories are of the same size and can be replaced with each other.

Mainly used for small displacement air compressors.

What are The Factors That Affect The Quality of The Oil Separator Filter?

a. MATERIAL

The material of the oil separator filter is the main factor affecting its service life.

The main material of the filter element is glass fiber, which has good filtering capacity and filtering precision. It also has the characteristics of high temperature resistance, good hydrophobicity and oil repellency, and excellent air circulation.

In addition to the filter material itself, the thickness of the glass fiber, the number of layers and the degree of uniformity are also key factors that determine quality.

Whether the shell and frame can resist changes in working pressure, the corrosion resistance and wear resistance of the sealing material can also affect the service life.

b. CRAFT LEVEL

Refers to the processing process of the oil separator filter.

For filter elements, good materials are not enough. The filter material can only determine the filtration accuracy, which means the smallest impuritie size that can filter out.

To manufacture a filter with excellent filtration efficiency, accurate testing and calculation are required during the production process, which is what we often call β test.

Whether to consider the initial pressure difference in manufacturing is also one of the factors affecting the service life of the oil separator filter.

c. DETAIL QUALITY

The workmanship and burrs of the sealing ring, the tightness of the glass fiber, and the configuration of the conductive sheet can all determine whether the oil separator filter can work efficiently.

Why does the oil separator filter burn or detonate?

In some situation, oil separator filter occasionally burn or explode in the oil storage tank during working. This situation is not caused by the oil separator element.

Because the filter material of the oil separator is glass fiber, it will not spontaneously ignite (unless your filter material is faked by chemical fiber).

And that combustion or detonation requires the simultaneous existence of fire and combustion-supporting gas.

The oil separator filter will generate static electricity due to the friction of gas or liquid, and the accumulation of static electricity will increase safety risks.

Therefore, the oil separator element needs conductive sheets or metal nails to eliminate static electricity.

In addition, the quality and the frequency of replacement of the oil can also become the reason of combustion or detonation. Poor quality oil will produce a large amount of carbon deposits. If not replace oil in time, these carbon deposits will block the safety valve and increase the internal pressure then cause the oil to burst.

Why Does The Air Compressor Leak Oil? What’s That Got to Do With Separator Element?

There are many reasons for air compressor oil leakage, such as: air compressor system failure, oil separator filter installation error, oil separation system design defects, oil separator filter quality, etc.

There are several common reasons that cause air compressor oil leakage:

- Minimum pressure valve failure;

- Unqualified oil;

- Non-standard oil and gas separation tank design;

- Too much fuel;

- Oil return check valve failure;

- Incorrect installation of oil return pipe;

- Increase in air consumption and use the machine under overload and low pressure environment;

- Blocked oil return line;

etc.

What Problems May be Caused by The Oil Separator Filter?

1. Failure of the minimum pressure valve will cause pressure imbalance. As the oil mist concentration under low pressure increases, the flow velocity when passing through the oil separator filter becomes faster. This will reduce the separation effect of the oil, resulting in higher fuel consumption

However, if the separation effect of the separator filter element itself is not good, it will also cause the pressure to rise and increase the fuel consumption.

2. If the filtering accuracy of the oil separator filter material does not meet the standard requirements, it cannot effectively separate the tiny oil particles in the oil mist. It will also lead to higher fuel consumption. The higher the machine temperature, the more serious the situation will be.

3. Improper installation of oil return pipe. Although it is not the quality of the oil separator filter, it has some relations.

The oil return pipe needs to be reinstalled when replacing the oil separator cartridge. If the oil return pipe cannot be inserted into the bottom of the oil separator cartridge, the separated oil will not be returned to the machine head in time.

The accumulated oil will run out with the compressed air.

4. The actual exhaust pressure is lower than the rated exhaust pressure. In this case, the air compressor will be in high-load operation for a long time, which will increase fuel consumption. Therefore, the exhaust gas customization requirements of the oil separator should also meet the actual situation.

5. There are many reasons for the blockage of the return line. It may be the entered impurities when replacing the oil separator filter, or the quality of the filter element is too poor to effectively filter impurities, etc.

How to choose the right replacement oil separator filter?

The easiest way:

1. Provide the model of the separator filter to be replaced.

2. Provide pictures of the separator element for reference.