Hydraulic Return Filter Manufacturer | DML

We provide professional hydraulic interchange filter and customized

KNOW DML

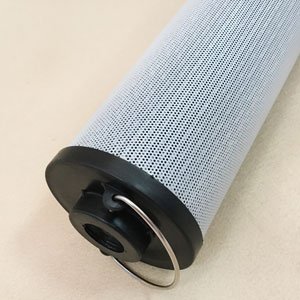

Hydraulic return filter in DML is mainly used in the hydraulic system of industrial equipment and heavy mobile equipment.

By installed on the oil return line of the system, it can effectively control the pollution concentration of hydraulic oil.

Housing includes: single-tube and double-tube type of hydraulic return line filter.

It also can be equipped with bypass valve, diffuser, transmitter, pressure balance valve, and other components.

The hydraulic filter element can be flexibly customized and produced. And it has interchange filter elements that can cover various brands and models.

It has advantages of good filtering performance, good oil flow capacity, and good reduction of original pressure loss.

Hydraulic Return Filter & Element

Single Cartridge Filter – Oil Return Housing

Reference display of some conventional hydraulic return filters, applicable to various industries.

Double Cylinder Filter-Oil Return Housing

The double-cylinder hydraulic return filter element can be replaced in the filter without stopping the main engine.

It can ensure the normal continuous operation of the machine.

You can change the working filter equipment by switching the steering valve, and then replace the filter element of the stopped return line filter.

Why Choose DML Hydraulic Return Filter?

Terminal Filter Element User

More than 20,000 replacement filter elements, covering most standard models.

Air freight, fast delivery | DHL, TNT, UPS, FEDEX, etc

Simple and efficient purchasing, choose your proper filter element with expert’s assistant.

Double or multilayer packaging, ensure safe and clean transportation.

Traders & Brands

Mature automated production line, independent customized production line.

10 years of ODM, OEM service experience for customers in Germany, Czech Republic, Romania, etc.

Brand printing services, screen printing, UV, offset printing, flex printing, etc.

Stable delivery, 1000 conventional filter elements can be produced within 10 days.

How to Get The Hydraulic Return Filter?

Interchange Filter

- Provide brand models number

- Provide reference pictures

How Does It?

1. The brand and model of the old filter element.

Generally on both ends of the filter element, printed on the end cap.

2. Provide photos of the components to be replaced.

Normally, only standard models are available.

The reference photo focuses on the positions of the two ends where the number (model) printed.

Hydraulic Return Filter Customized

You can give us some basic information such as:

- Use the environment, (Is it a kind of industrial equipment? What kind of mechanical equipment?)

- Filter media, (type or number of oil)

- System pressure,

etc.

Know More About Hydraulic Return Filter

Why Should Understanding The Return Filter

It is easy to choose a replacement filter element that meets the original filter element market standard, as long as you know the brand model, size, and working pressure, or even if you only know the filter parts number, we can help you solve the problem of replacing the original filter element.

But DML still recommends learning more about the common sense of the filter element.

Intermediary trader and the brand owner should learn more so that can serve terminal equipment customers better.

It is a win-win for customers and filter manufacturers.

Why?

It can be summarized as the following 4 points:

1. Customers with a correct understanding of the filter element will more easily distinguish the quality level of the filter element produced by the manufacturer, which is good for us.

Customer purchases will also be safer and more efficient.

2. In the production process, more data information can help us optimize filter element performance and increase customer viscosity.

The customers can also obtain the best filtration performance filter products on the basis of reducing procurement costs.

3. Complete information can increase the accuracy and practicability of filter element production, thereby reducing the risk to customers and manufacturers.

Since data information is often exchanged by mail or telephone, the integrity of information is very important to the production of filter elements.

4. Communication with professional customers can help us understand the information and problems about terminal using, to enhance our professional capabilities.

The optimization of the filter element is based on sufficient actual use data, it is meaningless to deviate from reality.

Looking for a high-quality oil return replacement filter element with low costs?

Which Points Need You to Pay Attention When Choosing?

Although the return oil filter is installed in the low-pressure pipeline, depending on the operating conditions of the transmission device, sometimes reversing oil may bring a large hydraulic shock.

So the material and strength of the filter element must be fully considered.

In addition, for simple circuit system structure and return oil filter element with low flow capacity, it is easier to cause blockage and backpressure in the circuit,(when overflow valve is used as a back pressure valve, the backpressure, is only related to the spring adjusting force instead of flow rate). Back pressure will cause the oil circuit to be blocked then reduce the efficiency of the entire system.

Compared with the high-pressure filter element or other pipeline filter elements, there are more actual use factors that need to be considered comprehensively before the oil return filter element is produced.

The Role of Optional Components

the return line filters can be equipped with a Bypass valve, Diffuser, Transmitter, Pressure balance valve, Proportional valve, Backpressure valve, Relief valve, and other components.

Pressure Balance Valve

When replacing the filter element of the double-tube filter, you need to turn on the pressure balance valve, Then turn the reversing valve, so that the other filter can participate in the hydraulic system.

It mainly adjusts the flow and pressure balance between the two filter cartridges of the filter to prevent the filter element from being damaged due to the instantaneous pressure difference generated during the changeover.

Reversing Valve

Which is the component used to switch the direction of the oil circuit.

Generally, DML adopts manual reversing valves in order to reduce operational risks, (when using charge type reversing valves, it is determined by the flow rate).

The selection of the reversing valve should also consider the inside maximum flow rate and working pressure, otherwise, it will increase the pressure loss and cause heat and noise of the system.

Bypass Valve

Mainly to provide a short-term oil bypass function when the filter element cannot be replaced during working time, (not a hydraulic bypass filter system).

In principle, the bypass valve is a short-term protection device for personnel maintenance errors or system emergencies.

But this method should not be used commonly, only replacing the filter element in time is the correct way to maintain equipment safety.

Buzzer

Pressure monitor, when the set system’s highest differential pressure (or other) rated value is triggered, an alarm will be triggered to remind the system operator to clean or replace the filter element.

Multiple methods are available:

- Differential pressure detection type,

- Pressure detection type,

- and Vacuum pressure type.

There are also notification forms through the display, sound, telecommunications, machinery, or can be connected to a computer for use.

Liquid Flow Diffuser

Increase the stability of the hydraulic oil when it returns to the tank, and it is not easy to produce bubbles.

Increase the stability of the hydraulic oil when it returns to the tank, thereby reducing the generation of bubbles.

In the process of customizing the filter, DML will help you design the product according to the actual requirements of the system, flow, pressure, cost, and other factors.

It is welcomed to talk to our manufacturing experts if you have any questions.