Air Compressor Filter Element | DML

Professional and cost-effective industrial filter manufacturer

KNOW DML

As a professional filter element manufacturer, DML have a mature air compressor filter element production process.

We provide regular replacement filter elements for most air compressor equipment on the market, as well as special filter elements customization and stable OEM/ODM services.

Mainly used for compressed air filter elements: air filter, oil filter, oil separator

Applicable industries include:

mining, metallurgy, machinery manufacturing, civil engineering, petrochemical, electronics, refrigeration and gas separation engineering, etc.

Which Kind Air Compressor Filter Do You Need?

Mainly to remove the liquid water, oil, and other impurities in the pipeline. Purify the air.

Oil-water Separation

Mainly to remove most of the liquid water and small amount of oil in the pipeline.

Coalescing Filter

Mainly remove the oil and small amount of misty water in the pipeline.

Applicable Air Compressor Type

1. Compressed air as power source

Compressed air is considered to be the second power source after electricity.

It has the characteristics of easy storage, easy control, good fluidity, safety, and environmental protection.

Depending on the pressure of the compressed air, it can drive a variety of pneumatic machinery, convert energy into automation devices, and store energy, etc.

2. Compressed air for refrigeration, separation

The air transforming of liquid by compressed, cooled and expanded.

Then can be used in refrigeration compressors for artificial refrigeration, and it can also separate mixed gas by temperature through a separation device.

Such as the separation and compression of petroleum cracked gas in the petrochemical industry.

3. Air compressor for transportation

Air compressors for pipeline transportation of gas,

such as coal gas transportation.

Air compressors for gas bottling,

such as oxygen cylinders and acetylene gas.

DML also provides air compressor filter elements for industrial equipment,

such as bottling of liquefied petroleum gas, gas delivery, and so on.

In fact,

No matter what kind of purpose it is,

the air compressor filter element is necessary to be used, as long as it’s compressed air, and no matter what different pressures.

If you are not sure which filter element you or your customer use.

Don’t worry,

DML will find out your needs based on the brand parts numbers or picture you provide.

If a customized product, you need to provide the corresponding size, outer diameter, pressure flow, or brands name.

Why Choose DML Air Compressor Filter Element?

Price Advantage

Help you save more than 50% of the air compressor filter elements replacement cost by our independent research and production.

Professional Customization

Customized product specifications and packaging. Provide you with accurate matching types, Short lead time.

Comprehensive Strength

DML has been engaged in ODM production for distributors in Germany, Czech Republic, Romania and other countries for many years

No MOQ

Order from 1 piece, Sample customization, Brand custom printing.

- Not sure which air compressor filter element to purchasing?

- Have brand operation plan?

- Is production quality unstable of existing supplier?

How To Purchase Air Compressor Filter Element?

Air Compressor Filter Element Customized

Custom plans need to meet the actual, the use environment, system requirements, and so on.

Contact our production experts to help you determine the core elements.

- Air volume design

- Operating temperature

- Dew point temperature

- Dust concentration at outlet or inlet

- Filter element pressure difference

- System working pressure

- Oil type

- Filter size

For reference,

We will guide you to the follow-up process simple and efficiently.

Choose The Proper Air Compressor Filter Element

As we know, the air compressor filter element refers to oil separation, oil filter, and air filter.

Whether used in power, refrigeration separation, or transportation, these three filter elements are essential elements for air compressors.

Most air compressor suppliers are able to help users to train, or guide operators in repairing, maintenance, and replacement of the air compressor filter element.

However,

some professional issues, It would be better for you should still be understood through filter element manufacturers.

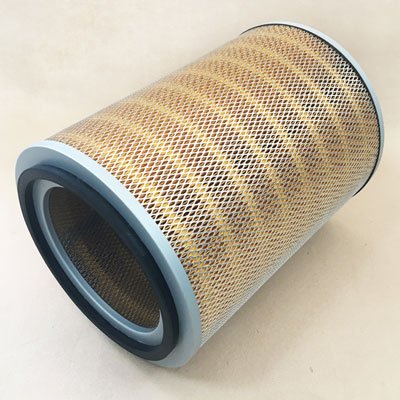

Air Compressor Oil Separation

The necessary filtration and separation equipment to reduce the oil content in the compressed air.

DML oil filter element is mainly composed of more than 23 layers of fiberglass, stainless steel frame, and anti-corrosion sealing ring according to system requirements.

The initial pressure difference can be optimized to below 0.02MPa.

Optimize the strength and filtration accuracy according to different pressure, temperatures, use environments, etc.

Ensure that the separation performance and service life of the oil separation core is 3500-5200h.

Oil Separation | Interchange Filter

Some of the standard filter parts show

You can find out the required filtration accuracy and other related data by the model number of the oil separation tank, or the old oil separation core in case you don’t find a similar oil separation core.

DML can also quickly match the replacement filter element by searching photos of your old oil separator core from our product library. (The oil separation filter element is installed in the oil separation tank. Since the oil separation tank is a pressure vessel, it generally has a unique number and certificate corresponding to its use requirements data.)

About Oil Separator Filter

The oil separation core determines the quality of the compressed air of the air compressor. The high-quality oil separation core can ensure the high efficiency of the compressor.

Although the role of oil separation core is mainly in gas-liquid separation, functionally it is still a filter element, which even has a higher filtration accuracy than an air filter and oil filter.

The filtration precision of DML oil separation can reach 0.1μm.

Like other filter elements, the oil separation element has a certain service life.

It is generally affected by the environment and air quality.

For example, in cement plants, wood processing, coal mining, and transportation with high dust content in the air, the use environment of air compressors is very bad.

Generally, the oil separation element should be replaced and maintained regularly before is blocked.

Otherwise, it will cause rising oil pressure, motor overload, increase energy consumption, the high temperature inside, and other chain reactions.

These problems not only affect the normal operation of the compressor but also affect the normal operation of the back-end purification equipment or gas-consuming equipment.

So a high-quality air compressor filter element is decisive.

The strength of the filter enclosure can withstand the operating pressure, while the filter capacity can adapt to the use environment to ensure service life.

Cannot be used twice or multiple times by backwashing.

Attention: All factors above determine that the price of oil separation core cannot below. Please be wary of cheap oil-separated core products.

The Following Methods Can be Used to Determine If The Oil Separation Core Should be Replaced.

1. Generally, the control panel will prompt if the oil is blocked

If not replaced in time, it will cause system abnormalities such as oil pressure rise, motor overload, over-current changes, etc.

2. Compressed air temperature rises

In air compressors, the primary problem caused by oil separation clogging is the high-temperature phenomenon, though the clogging will not directly lead to the reduction of exhaust volume (The volume flow of an air compressor refers to the airflow at the inlet of the air compressor).

However, the high-temperature phenomenon will increase the pressure difference between the front and rear of the intake air, directly causing the connecting hose to be flattened.

Frequent clogging will cause the hose to be deformed for a long time, and it will increase the number of hose replacements, indirectly increasing other costs.

3. The oil content of the air increases

Oil clogging will increase the oil content of the air and affect the quality of compressed air.

However, the oil content increase of the compressed air cannot be directly determined that caused by the blockage of the oil separator.

For example,

The damage of the oil separation core, blockage of the return line, low pressure of the compressed air pipeline system, failure of the pressure valve, etc., will also cause the increasing oil content in the compressed air.

The oil content expressed by the air compressor supplier such as ≤3PPm, in fact, is the filtration performance of the oil separator.

Sometimes just simply written as ≤2PPm.

Just like the hydraulic filter element,

The size of the filtration accuracy cannot determine it is good or not, the application of the filter element with 5μm and 10μm filtration accuracy is different.

The oil separation core should follow the original design and standard of the air compressor system.

Too high filtration accuracy will easily cause air compressor filter element blockage.

And also affect the use of subsequent components.

If you have high requirements for oil content, you can add compressed air purification treatment at the back end to increase water and oil removal, etc.

This not only ensures the good operation of the back-end gas equipment but also reduces unnecessary pressure on the compressor.

Therefore, a good oil separation replacement element must fit the equipment standards, have sufficient strength and filtering performance.

And fully consider the use environment factors are also needed.

The oil filter is divided into external screw-in type and built-in oil filter element.

It is one of the three common filter elements for air compressors.

The air compressor oil filter is mainly used to filter out: impurities generated during the operation of the system, the colloid produced by the oil due to heat and air oxidation and other impurities.

Engine oil containing impurities will: accelerate the wear of parts, cause blockage of the oil circuit, resulting in poor oil supply to the air compressor head and affect the life of the bearing.

The filtration precision of DML oil filter is generally 5-10μm, with the service life of 2000 hours.

Oil Filter | Interchange Filter

Suitable for replacement of most standard models air compressor filter elements, customizable.

External type

the built-in type

We all know that engine oil cleanliness is very important for air compressors, especially screw air compressors.

Moreover, it is expensive to replace oil and brand filter elements.

The high-quality air compressor oil filter can maintain a long-term cleanliness of the lubricating oil, reduce the wear of impurities and ensure the normal operation.

In addition, 80% of the performance and reliability of the screw compressor depend on the main engine. So the quality and performance of the machine head play a decisive role in the air compressor.

If the quality of the oil filter causes oil contamination. Even affects the performance of the machine head,

it is not worthwhile.

3 Suggestions on Air Compressor Oil Filter

1. Temperature

For air compressors that work in high temperature environments, the working temperature of the oil filter is generally high. So high temperature resistant fiberglass oil filter is needed.

2. Replacement

If your air compressor equipment does not have temperature control valve device, you need to replace the oil filter in time according to the PLC alarm. Otherwise it will have incalculable consequences for the machine head.

3. Standard

Same as hydraulic oil filters, the oil flow rate of each air compressor has been determined before sold. So changing oil flow is not allowed.

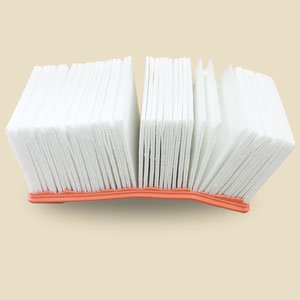

The first step in ensuring air quality

The cost of air filter in air compressor is lower than oil separation and oil filter, but the transportation cost is high.

For this reason,

many equipment users will repeated use air compressors air filter through reverse cleaning, in order to reduce replacement costs.

There are two main types of DML air filters for air compressors:

1. pocket filter

2. dust collector filter.

The conventional filtration accuracy standard is 5-10μm, and the use time is 2000h.

Air Filter Show

Dust Collector Filter

Pocket Filter

If there are production requirements for special models, or customization needs, you can provide product models or pictures as reference.

DML will quickly complete product manufacturing, and improving transportation safety by strengthening the outer packaging.

Here only shows part of DML air compressor air filters.

Contact us to get professional answer if you have any questions.

More About Air Compressor Air Filter

Your air compressor equipment supplier may sometimes remind you: to clean the air filter of the air compressor in time to ensure longer service life.

Such reminders even exist in the air compressor equipment maintenance manual.

For example,

The air filter must be blown backward with less than a certain bar of wind to achieve the purpose of cleaning without damaging it, or the air filter should be cleaned and maintained after several hundred hours of work, etc.

But as a professional filter manufacturer, it is recommended that do not save the cost on the service life of the air compressor filter.

Why?

Let’s briefly analyze the air filter of the air compressor:

Although the cost of the air filter is lower than oil separation and oil filter, it still has a replacement cost. It is a necessary expense for equipment users.

In order to divert customers’ attention from the cost of consumables, air compressor suppliers will shift their marketing focus to the sustainable use of filter elements.

After all, theoretically, a certain amount of wind can achieve the cleaning effect indeed, and it will not damage the air filter.

So the air filter becomes washable and reusable.

However, is the air compressor filter really suitable for cleaning and reuse?

Air filter, generally use dust filter cartridges as the first air purification barrier.

It filters out particles or impurities with a relatively large diameter.

Many dust filter cartridges do not have an all-metal structure, because they do not need to bear great pressure.

In addition, the air filter of an air compressor has a standard for filtration accuracy, so basically uses filter material such as filter paper and fiberglass.

For example, the DML air filter precision of the air compressor is 5-10μm. Those filter elements that can be reused through cleaning are only made by metal structures, such as hydraulic filter element with stainless steel metal mesh structure.

If the filter material of the filter element contains filter paper, fiberglass, etc., which is not allowed to clean and use again.

That because of local pressure changes, it is easy to cause damage or deformation of the filter element, which changes the filtration accuracy and reduces the filtration performance.

In addition, because of the adhesion of the air filter in the air compressor to impurities and the strength of the material, it is difficult to clean up by a certain amount of wind.

So, it is absolutely impossible to wash.

However, if the wind pressure is strong, the filter material will easily be damaged, and the cleaning effect will be small if the wind pressure is small.

We need to understand that:

A clean appearance of an air filter does not mean a good filter performance. Outside dust could hardly affect the performance, it still has a good filtering capacity, and it can ensure the service life of the oil separator.

However, if the fan is used improperly, the inside of the air filter in the air compressor may even be contaminated by dust, which causes more damage. In addition, whether the air filter is worth cleaning depends on the precision of the equipment. It is still allowed for dust filtering in a general factory.

Think about the cost of the oil separation core replacement.

Although the cost includes air filter and transportation is high.

It is understandable that everyone’s first thought about consumable’s cost is to save its cost as much as possible. However, this is an overall and logical-order filtering system.

For example,

The performance of oil separation and oil filter directly determines the efficiency and service life of the core components of the air compressor. The filter performance and usage of the air compressor air filter directly determine the service life of the oil separator and the oil filter.

It is equally important to ensure that they have the proper filtering performance.

Therefore, as a professional filter manufacturer, DML recommends not to save costs by cleaning the dust filter cartridge. Regularly replace the filter elements that should be replaced is the basic element to protect the operating life of the entire equipment.

If you have any questions about air compressor air filter, it is welcomed to contact our experts.

Contact Now