Air Compressor Oil Filter Element Manufacturer

- Complex Environment Adaptability

Water, corrosion, high-temperature resistance, and large dust holding capacity. - Stable Mechanical Properties

Resist system pressure, not easy to deform and break. - Multiple Product Types

Spin-on, and oil filter elements, replacement Compatibility 100%. - Reasonable Price, High-cost Performance

Save more than 35% replacement cost,long service life.

Replacement Original Filter Include:

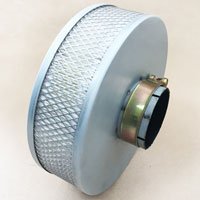

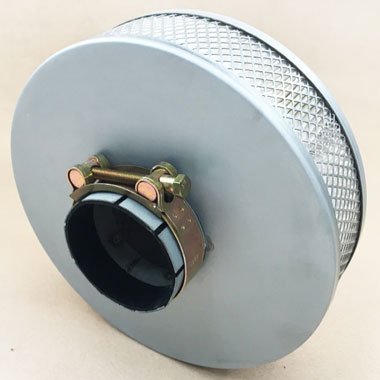

Replacement Air Compressor Oil Filter Element Products

Replacement Air Compressor Oil Filter Element

Atlas Copco Oil Filter PN#1622365200

Kaeser Oil Filter PN#6.4693.0B1

Gardner Denver Oil Filter PN#2118345

Gardner Denver Oil Filter PN#144606-02

Compair Oil Filter PN#A11380674

Almig screw compressor oil filter 57208791

Replacement Mann Compressor Spin-on Oil Filter ——

PN#WK731

PN#W962

Good Compressor Filter Supply Partner Could Help Your Business

About DML

If you are looking for air compressor oil filter, or other compressor filter brand interchange filter, etc., whether you are a device user, a trader, or a brand operator, believe that DML can be your best partner.

Our air compressor filter element can 100% match the original filter, suitable for various types of air compressors like screw compressor oil filter, volumetric type, piston type, etc.

Replacement filter has the same filtration efficiency as the original, while the price is more reasonable. That helps you significantly save on replacement costs and not worry about the effectiveness of its use.

Even flexible customization.

If you are operating your own filter brand, DML can also provide high-quality label printing services. In addition, our one-stop service can help you save time in purchasing other hydraulic filter, dust filter cartridges, high flow filter, and other industrial filter elements.

ADVANTAGES IN COMPRESSOR OIL FILTER PRODUCTION

Match your compressor oil filter element:

Please provide the parts number of the original oil filter element, if there is a reference picture of the original filter element, we will be more accurate for manufacturing replacement filter elements.

Please provide as many detailed requirements as possible to help you get feedback faster and comprehensively.

Mail to info@filterdml.com or send us via the form on the right

You will get a reply within 6 hours

Know More About Air Compressor Oil Filter

What is The Air Compressor Oil Filter?

Air compressor oil filter is used to remove out metal particles, solid impurities in the compressor lubricating oil, the dust that unfiltered by the dust collector cartridge, and impurities such as carbon, or floccule generated by chemical reactions caused by high temperature, water or other environmental factors

The purpose is to ensure the cleanliness of the oil system.

In this way, the oil entering the main engine is clean, which can protect the safety of the main engine, can be said that the oil filter element is the most important filtering part in the air compressor filtration system. Compared with compressor air filter, oil separator element, and other filter elements, it undertakes more filtering tasks.

Media and Standard of Oil Filter Element

High-quality air compressor oil filter, the media of it there are two materials commonly used:

- High Filter Rating Wood Fiber of Paper

- High Filter Rating Sintered Fiberglass

In addition, there are many so-called chemical fiber filter materials, but the filtering effect is very poor.

What Is The Difference Between The Both of Filter Materials?

The price, properly speaking

There is no standard price difference between wood fiber and sintered fiberglass material, on account of the quality of the filter element is different.

So, here we only distinguish from the effect

Wood fiber filter material is the oldest and most widely used filter media, which is the basic filter material used for various oil and gas filtration in a long time.

Advantages:

- High Filtration Rating

- Low Raw Material Cost

- Large Dirt Holding Capacity

- Long Service Life

The disadvantages are also obvious.

It is easy to be carbonized at high temperatures and has poor water resistance, etc.

In contrast,

The fiberglass material has the advantages of high-temperature resistance, corrosion resistance, waterproof, and deep filtration ability.

The disadvantage is that fiberglass has poor ductility and is relatively brittle. If the quality is poor, it may even fall off. It will not conducive to the filtration of the oil line.

Why Choose High-quality Air Compressor Oil Filter?

The filtration of the compressor oil line system requires not just the oil filter with excellent filtration efficiency, and filtration various impurities in the oil is only one of the functions of the filter element.

At the same time, the high-quality filter element must be able to cope with the complex use environment.

The good filter element can be used for a long time without worrying about blocking, or damage affecting the filtering effect. And therefore, the number of downtime maintenance will not increase due to the failure of the oil filter element, will not increase the cost of equipment operation and maintenance

So, from the perspective of the operator’s operation

High-quality oil filter element

It can reduce the replacement cost of oil, other filter elements and equipment parts, and reduce the failure rate of air compressor equipment, maintain work efficiency, and save energy consumption. Which can also increase the service life of the machine and reduce maintenance costs

Which Quality Problems of Filter Cause Compressor Failures? How to Judge?

Poor oil filter quality usually causes below problems:

- Easily clogged

- The filter media is carbonized

- Deformed, or Ruptured

- and so on

Which causing problems such as the high-temperature of the system, oil leakage, abnormal noise of the main engine, jamming of the machine head, damage to the bearing, etc.

Quality Problems:

1. Easily Clogged or Never Not

As we know, if the filter element never clogged, that will definitely not be a manifestation of high filtration efficiency, just means it has no filtering ability.

There are many reasons for clogging:

A, Filter Rating Higher Than The Rated Standard

The filter media rating is related to the filtering capacity of the element.

But if the filter rating is too high, the blockage is not only caused by the filtered impurities, but also the flow rate of the oil through the filter element decreases, the resistance increases, and the pressure difference increases, which causes the filter element to clog.

This is caused by the incorrect selection of filter media ratings when producing oil filter elements.

B, Low Dirt Holding Capacity

Also named dust holding, Indicates the surface area of the filter element to absorb impurities, larger the filter media area, the stronger of dust holding capacity, the less likely it is to clog up for oil filter.

Although it is possible to increase the dust holding capacity by changing the size of the oil filter element. But the filtration parts of the compressor are already a standard model, it’s difficult if you want to change the filter element to make a bigger size.

Is there another way?

The better idea,

increase to extend the alarm time of the filter element blockage by reducing the initial pressure difference. That will make the service life longer

The good industrial filter element manufacturers could do that.

Please notice, poor-quality filter elements will reduce the cost by reducing the surface area of filter media to reduce the price.

For example,

Reduce the number of pleats of the oil filter media.

Reduce the height of the filter media pleats

And so on

This kind of oil filter not only has a bad filtration effect but also has great invisible damage to the compressor oil system. Cheap is the “only advantage” of this filter.

C, Poor Water Resistance

The filter paper with low water resistance will easily make the oil filter element clogged when there’s much water.

This situation happened in the filter media mainly made of wood fiber (especially the wood pulp filter material mixed with starch, the solidification technology is not standard, etc.)

The filter pore size will be reduced cause the wood fiber of filter paper is affected by water (inducing absorption and expansion).

It will impede the flow of oil and cause clogging. Moreover, the increase of moisture will deform the filter pleats and stick together, which will greatly reduce the filtration efficiency of the oil filter.

So why is there water in the pipeline?

For example,

- There is water in the air.

There will be water mixed in the oil after the gas-liquid separation of the separator element. - The oil needs a cooling system except for being used for lubrication, and the oil itself also contains a certain amount of water.

- When the air compressor is running at low temperature or low frequency, the water vapor is easier to liquefy and condense into more water droplets.

- and so on

Therefore, that’s better to choose the oil filter element which used sintered glass filter media, if there is an operating environment with a lot of moisture or the characteristics of the equipment itself.

D, Can’t Bear High-temperature

You need to know, the filter paper will be carbonized if the filter media isn’t bear high temperatures.

it will be fragile and cause the filter element to clog after the paper is carbonized.

The clogging of the filter element will cause a high temperature in the system, which is a vicious circle.

So, it is better to choose a high-temperature resistant material for a filter element that is often operated in a high-temperature environment, like sintered glass fibers.

2. The oil filter is deformed, broken, perforated, or leaked

Generally, there are two main situations that cause destructive damage to the oil filter:

- Poor quality

- Incorrect installation or use

If wrong installed or used, the filter element will usually be broken down or deformed by the moment pressure of the system.

and the end cap, sealing interface, side, bottom, etc.

So what faults can quality problems cause?

A, Insufficient Mechanical Strength

The air compressor oil filter that failed the ISO2941 test has insufficient mechanical strength

This will result in low compressive strength of the filter element. It will also easily cause the sealing ring to burst, bottom perforation, cracking at the seal, and extrusion deformation.

The reason is very simple,

Either the manufacturer’s level is not enough, or the material is reduced in order to reduce the price

The level of the manufacturer is mainly reflected in whether the sealing technique is good or not, which is easy to distinguish.

There is another cause – cutting corners

Common such as thinning the steel thickness of the shell, frame, or end cap.

Although the thickness of the shell is not the main reason for the bottom perforated, it is also related (and the material of steel).

Or the oil leakage at the seal is mainly because the threaded plate is too thin, or the differential pressure of the filter element rises. It will deform and cause the seal to loosen and leak oil when subjected to high pressure

Although these problems are not easy to find by appearance, they can still be judged according to the weight and solidity of the filter element product.

B, Poor Corrosion Resistance

The corrosion resistance is related to the quality of the filter media,

There are many reasons for corrosivity, such as:

- Oil oxidation (oxidation will produce lactic acid in the oil and increase the acid corrosion of the fluid)

- Temperature change (low-temperature environment will produce more water, causing flocs to be acidic; the high-temperature environment will change the properties of the sealing material)

- Environmental factors (plastic factories, chemical plants, etc. contain certain corrosiveness in the air)

They are all factors that increase the corrosion in the filtration system.

That may erode the bottom of the oil filter and make a hole, if there is a problem with the media of the filter element, although the probability is very low.

And the oil will leak on account of the sealing error because the seal ring shrinks or is corroded.

Therefore, paying attention to these details is for the compressor equipment safe.

Which Factors Need to Be Considered WhenThe Compressor Oil Filter Production?

Replacement Filter Element

It will be manufactured in full accordance with the data parameters of the original filter element unless there are customization needs. Compatibility 100% is necessary.

So generally provide the original filter parts number, a mature compressor filter manufacturer have a complete design drawing database as a reference.

If you can provide the filter photos, the production of replacement filter elements will be more in line with the requirements

Custom Filter Element

The customization requires, need to reasonable design and production of air compressor oil filter elements according to specific conditions.

I. Cleanliness of Air Compressor Oil System

Oil cleanliness standards generally have specified the filtration rating of filter elements and other indicators.

It can also be designed based on the data parameters of air compressors, internal combustion engines, and other equipment

II. The Characteristics of The Oil

The type of oil is a very important indicator.

Because different types of air compressors require suited oil.

The model, type, and nature of the compressor oil, also determine the thickness, number of pleats, and type of the filter element.

Therefore,

the use environment, system parameters, oil properties, requirements, and other factors should be considered comprehensively when designing filter elements.

III. Remove The Types of Impurities

The impurities contained in the oil can also affect the media choice of the filter element.

Such as humidity, temperature, acidity and alkalinity, organic solvent content, the hardness of impurities, etc.

The oil filter element needs to be able to adapt to these properties in order to work properly.

So we need to choose materials or process methods based on these.

Like high-temperature resistance, corrosion resistance, or certain waterproof performance, etc.

IV. The Characteristics of Air Compressor Oil Filter

According to the rated requirements, try to choose an oil filter with good filtration efficiency, low resistance, high dirt holding capacity, high mechanical strength, and reasonable filter materials.

For example, when the frequency conversion screw air compressor is used at low frequency, the pressure of the oil circuit system will be low, and the oil filter must have low resistance and good air permeability.

Why Choose DML to Replacement Filter Element

As a professional industrial filter element manufacturer.

DML can not only provide compressor oil filter, oil separator elements, compressor air filter, and other filtration parts products.

We also provide hydraulic filter elements suitable for mechanical equipment and heavy-duty, dust collector filter for air purification, high-flow filter cartridge for industrial wastewater treatment, and filter elements such as winding filters, and so on.

You can quickly obtain high-quality, reasonably-priced filter products by providing the parts number of the filter element that needs to be replaced