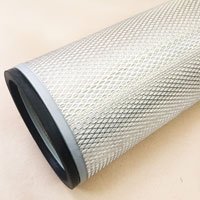

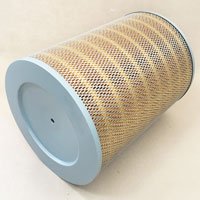

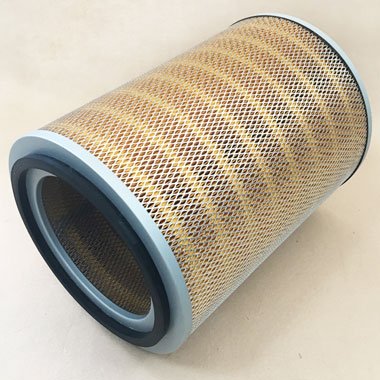

Air Compressor Air Filter Element Manufacturer

- High Filtration Efficiency – Effectively filter air particulate impurities

- Suitable Flow Resistance – Stable filtration efficiency and air volume

- Wide Range of Applications – Direct Replace Other Brands & Product Compatibility 100%

- Long Service Life – Reasonable price, Save over 35% replacement cost

Replacement Brands Include:

Part of Replacement Compressor Air Filter Element

Replacement Atlas Copco Compressor Air Filter Element

PN#1622185501

PN#1622065800

Replacement Sullair Dust Collector Filter

PN#02250135-148

PN#02250135-149

Replacement Ingersoll Rand Air Compressor Filter

PN#54717145-152

PN#25-24172215

PN#22338115

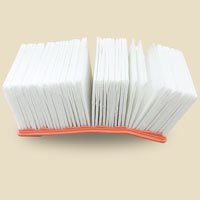

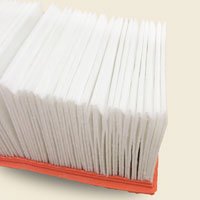

Filter Accuracy: 5~10 microns

Filtration Efficiency: 98%

Over 2000h Working Time

Pure wood pulp filter material imported from HV & Ahistrom company

Ordering Requirements:

Provide parts number or picture as a reference

The more detailed information provided to us about replacement filter, the better performance of the filter element can be achieved when manufacturing.

Such as: Air compressor model, filter element diameter and height, (Customized products provide rated power, flow, and other mechanical requirements)

Good Compressor Filter Supply Partner Could Help Your Business

About DML

If you are looking for compressor air filter element to replace original filter, such as: Atlas Copco air filter, etc brand filter parts, or customized dust collector filter, etc.,

Whether you are compressor owner, trader, or brand operator, believe DML can be your best partner

The air filter cartridges we provide can completely match the original products.

The replacement filter has the same filtration efficiency as the original brand filter. Reasonable prices help you get a high-quality air compressor air filter, and also greatly saving the replace pay.

If you are running a brand, or in preparation, DML can also provide high-quality and diversified label printing services.

At the same time, we have more types of filter elements, like compressor separator elements (oil filter…), compressed air filter, hydraulic filter elements, etc. to meet your various needs and help you save purchasing time

ADVANTAGES IN COMPRESSOR AIR FILTER PRODUCTION

Now, start to match your exclusive compressor air filter element.

Please provide the parts number of the original filter

Of course it’s better plus a photo as reference

If you can provide more detailed requirements, that will get our faster and more comprehensive feedback.

Mail to info@filterdml.com, or send message via the form on the right

You will get reply within 6 hours.

Know More About Compressor Air Filter

What is The Air Compressor Air Filter Element?

Air compressor air filter is mainly used in pneumatic machinery, internal combustion engine machinery, and so on.

As a dust collector filter, it could provide clean compressed air for this equipment.

Its filtration can prevent mechanical equipment from inhaling air contain impurities during work. In this way, which can avoid increasing the probability of machine damage due to wear.

Quality Dust Collector Filter Requirements

The high-quality dust collector filter fits 3 basic requirements:

- Good Efficiency.

Could be undertaking high-efficiency air filtration work. - Low Pressure, High Air Volume, Good Stability.

It will not increase too much resistance when the air flows through the filter element. - High Dust Holding.

Long time to work continuously, which can reduce downtime and maintenance time.

Why Choose High-quality Compressor Dust Collector Filter?

The dust filter cartridge is one of the indispensable components of the air compressor operating system.

But it is often ignored by users.

We found that some customers maintain the air filter by beat, blowing, or even washing without any protective measures.

However, this kind of maintenance method may cause multiple pollution or damage inside the filter cartridge, which is not worth promoting.

The various problems that usually occur in air compressor,

such as high temperature, oil leakage, abnormal noise of the main engine, jamming of the machine head, bearing damage, coking of lubricating oil, and deflated intake hoses, etc.

May be caused by the failure of the air filter.

What Are The Common Problems?

1. Increasing Intake of Differential Pressure, Energy Consumption, and Operating Costs.

If it is because of the low filtration performance of the dust collector filter, the air intake will be reduced and the differential pressure of the filter will increase. It will reduce the working efficiency of the system, and may cause the intake connecting hose to suck flat.

If it is due to insufficient filtration accuracy and poor filtration efficiency, although it will not affect the flow of air intake, it will cause more serious machine failures due to the inability to effectively filter the impurities in the air.

2. Lubricating Oil Cleanliness Drops

If the filtration accuracy or filtration efficiency not good, a large amount of dust and impurities will be mixed into the lubrication system.

It will decrease the cleanliness of the oil.

Contaminated lubricating oil will affect the main engine rotor, bearings, and other precision parts.

Reduced efficiency of the main engine will reduce the service life of the air compressor

At the same time, it will also reduce the service life of other filter equipment of the air compressor equipment.

3. Oil Separator Element Blockage

Contaminated oil will affect the oil separation system of the air compressor. Which causing the separator element blockage, and reducing the efficiency of oil and gas separation.

The reduction of oil and gas separation efficiency will increase the oil content after the separation of air.

That will reduce the quality of compressed air and affect the application of subsequent equipment.

If the oil separation filter element is blocked badly, the resistance will increase and the system pressure same too.

The separator element will be deformed In severe cases, which may cause serious oil leakage in the system.

4. Air Compressor Oil Filter Blockage

The oil filter is the main element to keep the oil clean.

However, if the quality of the dust collector filter is not good, it will increase the burden on the compressor oil filter.

Such as reducing the service life of the oil filter, and increasing the replacement cost.

the machine will works in the low efficient situation because of the increasing differential pressure, and even causing the system to overheat In severe cases.

What Factors Need to Be Considered Before Compressor Air Filter Producing?

Replacement Filter Compatible 100%

DML a mature compressor filter manufacturer which have a complete design drawing database.

The replacement filter element will be manufactured in full accordance with the data parameters of the original filter that never changed.

So, generally just providing the parts number will be OK.

Of course better to provide the photo to reference, which will make the replacement filter more in line with the requirements.

Custom Filter Element

Customization compressor filter element design and production according to the specific conditions.

1. Indoor Purification Standards for Your Equipment

Purification standards generally have specified the filtration accuracy of filter elements and other indicators.

It can also be designed based on the parameters of air compressors, internal combustion engines, and other equipment.

2. The Type of Dust Content & Impurity Content In The Air

Because the air compressor needs to filter and purify the air before using it for other purposes, so the amount of dust content in the air is a very important indicator.

The concentration of dust in the air, the shape, and nature of dust particles also determine the use, thickness, number of pleats, area, etc. of the filter element.

Therefore, in the design, especially when multi-stage filter elements are involved, factors such as the use environment, spare parts costs, operating energy consumption, maintenance, and supply costs should be comprehensively considered.

3. The Nature of The Gas

The nature of the gas is determined by the impurities it contains.

For example:

humidity, temperature, acid-base level, organic solvent content, etc.,

The air filter needs to adapt to these properties to work properly.

So you need to select materials and process methods based on this information.

Such as high-temperature resistance, corrosion resistance, or certain waterproof performance, etc.

4. The Characteristics of The Air Compressor Filter Element

If possible, try to choose parts with the characters of high filtration efficiency, low resistance, large dust holding capacity, filtration wind speed in line with system requirements, large processing air volume, and stable flow.

How to Determine The Quality of Compressor Dust Collector Filter?

We all know that “you get what you pay for,” and the same goes for the air compressor air filter element.

We cannot deny that there are high-quality and inexpensive products.

But if the price is too lower than the market price, the filter element must have quality problems.

So Where Does It Reflect?

I. FILTER ACCURACY & FILTRATION EFFICIENCY

The filtering accuracy directly reflects the quality of the filter media.

If the filter media is produced by the filter factory itself, it needs to be tested to determine the filter accuracy.

In comparison, most of the manufacturers’ filter media are purchased, which is also one of the factors that contribute to the price difference of filter elements.

After all, there are different grades of filter media.

A good filter media has a uniform and stable fiber filter structure.

Professional compressor filter element manufacturers have their own testing equipment. They use this equipment to test the filtration capacity of the filter to ensure good filtration capacity.

And what – the filter efficiency is actually different from the filtration accuracy.

High-performance filtration efficiency is achieved through strict design and production processes.

It is not all determined by the filter accuracy of the filter media itself.

Therefore, it is an aspect that best reflects the supplier’s ability level

The quality of the filter element whose filtration efficiency cannot meet the actual standard must be poor.

II. FILTER AREA

The filter area determines the dust holding capacity of the element.

Increased dust holding capacity can directly increase the service life of the element. That can absorb more impurities without obstructing the air circulation.

However, the size of most original filter elements has been fixed and it is difficult to further optimize.

If it is customized, which very friendly to actual use if the manufacturer maximizes the dust holding capacity.

For example,

Increase the number of pleats of the filter material, of course, these also need to consider factors such as air resistance

So, it is easier to distinguish the quality of the element through the filter area.

Poor quality filter elements will reduce the cost by reducing the number of pleats, or the height of the pleats

This will reduce the filter area and fail to get a due filter effect.

III. MECHANICAL STRENGTH & SEALING

Although the air filter does not need to bear a strong working pressure or high temperature like a hydraulic oil filter element.

But it will also be affected by environmental or system pressure, so it should not be ignored.

IV. CHANGES IN SIZE, SHAPE, AND INTERFACE

Some errors are inevitable.

After all, the complexity of air compressor filter elements, and the diversity of air compressor models determine that each batch of original filter elements has subtle differences or small errors in production.

Replacement filters also have a similar situation.

Even those well-known labels.

However, as long as it is not due to deliberate non-standardized changes to air compressors, or internal combustion engine equipment, the error of element will not exceed the scope of the standard.

If so, it must be a production-quality problem.

Why Choose DML to Replacement Compressor Filter Element?

As a professional filter manufacturer, DML not only provides compressor air filter, separator elements, compressed air filter element, and other filtration products but also includes hydraulic filter suitable for mechanical equipment and heavy-duty.

The dust filter cartridges for air purification, high-flow filter element for industrial wastewater treatment, and elements such as winding filter.

Reduce cost expenses is the main reason people choose the replacement filter elements.

For example, users who purchase a branded car will choose to maintain it at the 4S station during the warranty period.

The same goes for machinery.

The probability of choosing the original product during the warranty period is relatively high, but once the warranty period has passed, customers will looking for the replacement filter.

Because the original filter and some brands that have passed the certification of mechanical equipment have a certain brand premium space.

In this way, the customer’s replacement cost is still high.

Therefore, in the end, quite a few customers will choose a filter manufacturer with a lower price but with the same filtration efficiency.

You can quickly obtain high-quality, reasonably-priced filter products from DML by providing the Parts number of the filter element that needs to be replaced.