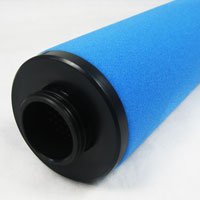

Compressed Air Filter Elements Manufacturer

- Excellent Filter Media

Larger effective filtration area and higher dirt holding capacity - Advanced Filtration Technology

Relatively low initial differential pressure and a high flow rate - Replacement Filter Element

100% compatibility with many original filter on the market - Reasonable Price

Save more than 35% replacement cost, long service life - Deliver Fast

Automated production line, quick shipping from the factory

Cross-reference Brands List:

Compressed Air Filter Elements Replacement Product

Donaldson Ultrafilter

Hankison Air Filter

Orion Compressed Air Filter Elements

SMC Air Compressor Filter

BOGE Filter Element

Wilkerson Compressed Air Filter Elements

AFE

KAESER

DELTECH

APUREDA

NORGREN

Your Quality Compressed Air Filter Elements Manufacturer Partner

About DML

Are you looking for compressed air filter elements or other industrial filter elements to replace the original filter?

As users, traders, or brand owners who use it for various compressed air filtration equipment, such as manufacturers of petroleum and chemical plants.

Believe that DML can be your best partner for the establishment and maintenance of filtration equipment.

Our filter parts can be 100% compatible with the original filter, use for various types of compressors like screw compressor oil filter, volumetric type, piston type, etc.

And other kinds of filter elements for the compressor:

- Dust collector filter

- Separator elements

- Compressor oil filter

- Hydraulic filter elements

- and so on

The replacement filter element has the same filtration efficiency as the original. And the price is reasonable, which can save more replacement costs for you.

In addition, our flexible private label custom services, and Separate production line support make your one-stop shopping and save time

ADVANTAGES IN COMPRESSED AIR FILTER ELEMENTS PRODUCTION

Select Your Replacement Compressed Air Filter Elements

The parts number of compressor filter elements is so much

So, please tell us:

- The parts number of the required filter elements

- The photos of the used filter element as reference

Notice:

The other filter elements you wanna make replacement, [ such as hydraulic filter, air filter, or fluid filter, etc ], please let me know that parts number too.

(The numbers are printed on the cap of the filter element)

Contact us through the form on the right, you will get reply within 6 hours

or send message to info@filterdml.com

Any questions will be answered

Know More About Compressed Air Filter Elements

What is Compressed Air Filter Elements?

As the name suggests – filter elements for compressed air, also called precision filter elements.

Well-known brands are Donaldson, Ultrafilter, Atlas Copco, Hankison, and so on. Many of them are world-renowned air compressor equipment suppliers.

This kind of filter element is mainly used for the filtration of compressor compressed air. It is a component of the subsequent filter equipment of the air compressor

It can remove impurities like oil, water, particles, bacteria, and even odors in the air, as well as maintain the cleanliness of the air compressed.

Applicable Industries

pharmacy, chemical industry, food, environmental protection, textile, beauty production, gas transportation, pneumatic equipment, metallurgy, electromechanical, etc.

Use the different filter media in different industries.

In addition to sponges and skeletons, materials such as sintered glass fiber or string wound, pp and so on are also used

For example,

the filter element that uses sintered glass fiber as the main filter material will be used in filtration environments with relatively high oil content.

Because of this, the precision filter element has a higher filtration rating and filtration efficiency.

Most of them are in the micron range, the most commonly used are:

- 5 micron compressed air filter

- 1 micron compressed air filter

Even submicronic compressed air filter

Such as:

- 0.2 micron compressed air filter

- compressed air filter 0.01 micron

Precision filter elements generally do not use any adhesive.

The fiber structure of the filter material has high toughness and high porosity

Therefore, it has the advantages of small pressure difference, small resistance, and fast water and oil repellency, which can greatly improve the filtration efficiency.

In addition, the high-quality stainless steel structure can withstand sufficient system pressure.

It can also increase the support ring to enhance the mechanical strength of the filter element,

Why Use The Air Compressor Filter?

More than 90% of factories in the world use compressed air in the manufacturing process.

Although compressed air is the second-largest power source after electricity, there are also problems such as compressed air pollution

Therefore, all manufacturers that use air compressor equipment must follow the ISO 8573-1 (2010) compressed air standard.

Determines the air quality level that should be selected,

especially if it contains oil mist, water vapor, particulate impurities, etc.

Because compressed air contains these impurities, it is best to filter the compressed air before use.

The location and use of compressed air are the basis for determining air quality standards.

By properly filtering compressed air, you can get clean and dry compressed air, while ensuring the safety of use, it can also save subsequent equipment maintenance work.

Such as:

- Aftercooler

- Compressed Air Filters

- Breathing Air

- Adsorption Dryers

- Measuring Equipment

- Compressed Air Vessel

- and so on…

Understanding the Filtration in Compressed Air System

What is The Compressed Air Filtration?

Use porous media to remove pollutants (oil mist, water vapor, particulate impurities, bacteria, viruses, etc.) from the air.

Principle of Filtering

1. Direct Intercept

According to the diameter of the filter pore size, directly intercept the impurities whose particle diameter is larger than the filter pore size (filtration precision) or the flow channel pore size.

Filtration particles up to sub-micron level.

2. Inertial Impact

Particles whose size is smaller than the pore size (filtration accuracy) of the filter material. Driven by airflow and inertial velocity caused by particle mass, etc.

It will be adsorbed and intercepted when it hits the fiber of the filter material, which is very effective for micron particles.

3. Diffusion Interception

The Brownian motion of nano-scale particles in the gas will form irregular flow paths, the multi-level filter material combination and deep filter structure of the compressed air filter elements can increase the filter efficiency.

4. Electrostatic attraction

The static charge of the filter layer fibers can electrostatically adsorb virus individuals or aerosols smaller than the diameter of the filter hole.

Filtering Criteria

1. Filtration Rating

According to ISO8573-1-2010 standard and equipment requirements to determine the diameter of the filter material to be filtered

2. Filtration Efficiency β

Evaluation of filter media mainly depends on whether the actual filtration rating meets the standard and whether it can effectively filter impurities.

But the most important thing to evaluate the filter element is its filtration efficiency, which is related to air resistance, flow rate, filtration area, and other factors.

3. Pressure Difference/ Pressure Drop

The pressure difference of the filtered fluid between the inside and outside of the filter element is caused by fluid resistance and filter blockage

A good quality filter element has a lower initial pressure difference. The alarm time of the rated pressure difference can be delayed, which indirectly increases the service life

What Are The Factors That Affect The Pressure Drop of The Filter Element?

There are two main considerations: initial pressure difference, and filter pressure drop

Initial Pressure Difference:

The density of the filter fiber and the thickness of the filter layer are the main factors that affect the initial pressure difference.

- The filter material with low packing density and low resistance has small pressure drop;

- The filter layer is thin, and the initial pressure drop is also small.

But it can also be accurately designed to ensure lower resistance while reducing the initial pressure difference to increase working time.

The main factors affecting the filtration pressure drop:

- The concentration of impurities in the air

- The airflow rate through the filter element. The faster the speed, the faster the filtration pressure drop increases.

- The configuration of the compressed air filter element. The higher the ratings, the faster the high-pressure drop increases.

- The nature of the filter medium will also affect the pressure drop.

4. Filter Area

For the same filter element volume,

if the number and height of pleats are different, the filter area can be increased or decreased by nearly 5~13 times.

An increase in the filter area will increase the dirt holding capacity of the compressed air filter element.

The service life will be greatly extended

But the filter area and resistance are inversely proportional.

We need to balance the standards between them

Factors Affecting Compressed Air Quality

The quality of compressed air is mainly determined by the content of solid particles, water, and oil in the air.

These three substances have a great impact on the air compressor system equipment and compressed air quality, and the moisture is mainly removed by separation and drying, while the solid particles and oil are mainly removed by filtration.

We have already mentioned a lot about the filtration of solid particles and impurities in the oil.

So, the next point:

Effect of moisture on compressed air

Why There is Water in Compressed Air

1. The Content of Liquid Water in The Air Exceeds The Standard

How does liquid water come from?

When air is compressed by an air compressor, part of the water vapor in the air will condense into liquid water.

The separated water is discharged through the drain valve at the bottom of the filter element.

But the compressed air will be mixed with sludge, dust, and other impurities that will block the drain.

As a result, the separated liquid water cannot be discharged

The dryer before the air storage tank can remove the gaseous water in the compressed air, but cannot filter the condensed liquid water in the tank.

The increase in the content of liquid water will reduce the adsorption capacity of the adsorbent in the adsorption tower.

It will make the dew point rise.

If the adsorbent is broken, it may clog the filter and even contaminate the gas tank.

However, when the compressed air storage tank is not manually discharged in time and the drainage effect is poor, the moisture in the compressed air cannot be removed in time.

Especially in winter, it is easy to freeze, which will cause the liquid water in the compressed air to be discharged through the pipe

2. Exhaust Temperature of Air Compressor is Too High

This problem is more likely to occur when the equipment runs in a high temperature and closed environment.

At high temperatures, compressed air mostly exists in the form of water vapor.

Transmission in the pipeline will condense due to gradual heat dissipation, an increase in liquid water will increase the difficulty of separation, which will bring more water into the subsequent system.

The problem is even worse when the temperature difference is large in winter.

What caused this?

In actual use

The exhaust temperature of the air compressor is usually higher than the value of the design temperature, which will decrease the dehumidification effect of the dryer.

This is because after passing through the oil cooler, the hot air will be directly discharged into the surrounding environment through the fan

Since the suction port of the air compressor is very close to the exhaust port, in a closed environment, part of the discharged hot air will be sucked in again.

The exhaust temperature of the compressed air will always be high.

For example, it may reach over 50°C in summer

In addition to environmental factors, there are also reasons for the equipment itself, like lack of oil, clogged filters and coolers will increase the energy consumption of the air compressor, that will make the exhaust temperature up.

3. Dryer Failure

The main is that the adsorbent in the dryer has insufficient regeneration capacity for some reason, so the water removal effect of the adsorbent cannot be fully utilized

4. Water Accumulation in The Gas Storage Tank

As mentioned above, the partly liquid water accumulated in the air tank will be taken away by the compressed air.

It will be delivered to all gas-consuming parts through the various gas pipelines of the compressor.

So, in order to solve the problem of water in the air as much as possible, that’s why the compressed air filter adds the sponge as filter media.

What Kind of Filter Element Used For Compressed Air Means High-quality?

Good compressed air filter elements need to deal with various complex working environments

- Pressure changes caused by unused circumstances

- Can adapt to sudden changes in air velocity

- Good sealing,

- Changes in temperature and humidity

- Excellent filtration efficiency

- Chemical resistance and filtration

- Long service life

Why DML Can Replace The Compressed Air Filter Elements of The Original?

Why not?

The replacement Filter Element,

- Compatibility 100%

- Excellent filtration efficiency

- Long service life

- Save your replacement cost over 35% than the original filter element

I think there is no reason to refuse this product

For example, if you buy a branded car, during the warranty period, you will choose to maintain it in a 4S shop.

Same as machinery and equipment,

The probability of choosing the original product during the warranty period is relatively large.

But after the warranty period, customers will look for alternatives.

People instinctively look for more affordable products.

After all, the replacement cost of the original filter element is relatively high. That is very good for the manufacturer who gets a filter element that can replace and save production costs,

As a professional filter element manufacturer,

DML can not only provide air compressor oil filter, oil separator elements, air compressor air filter elements, and other products.

We also produce filter elements such as hydraulic filter elements suitable for mechanical equipment and heavy mobile equipment, dust filter cartridges for air purification, large flow water filters for industrial wastewater treatment, and wire-wound filter elements, etc.

You can quickly obtain high-quality and reasonably priced filter products by providing the model of the filter element that needs to be replaced